Back in the mid-1980s, aircraft system integration was part of my stock-in-trade. Project managing the integration of a safety critical system into a large new helicopter. It was a challenging but rewarding job. Rewarding in that there was a successful new aircraft at the end of the day.

For big and expensive development projects there are a great number of risks. The technical ones focus on functionality, performance, and safety. The commercial ones focus on getting the job done on-time and at a reasonable price. Project managers are in the middle of that sandwich.

Naturally, the expectations of corporate managers in the companies that take on these big challenges is that systems and equipment integration can be done to the book. Quickly and without unexpected outcomes. The practical reality is that people must be well prepared and extremely lucky not to encounter setbacks and resets. It’s not just test failures and anomalies that must be investigated and addressed. Systems integrators are working on shifting sand. The more that is known about overall aircraft flight test performance and customers preferences so technical specifications change.

With cockpit display systems, in the early days, that was often feedback from customer pilots who called for changes to the colour, size or shape of the symbology that was displayed on their screens. What can seem a simple post-flight debriefing remark could then turn into a huge change programme.

That was particularly true of safety critical software-based systems. Equipment suppliers may have advanced their design to a state where much of the expensive design validation and verification was complete. Then a system integrator comes up with a whole set of change that need to be done without additional costs and delivered super-fast. Once a flight test programme gets going it can’t be stopped without serious implications. It’s a highly dynamic situation[1].

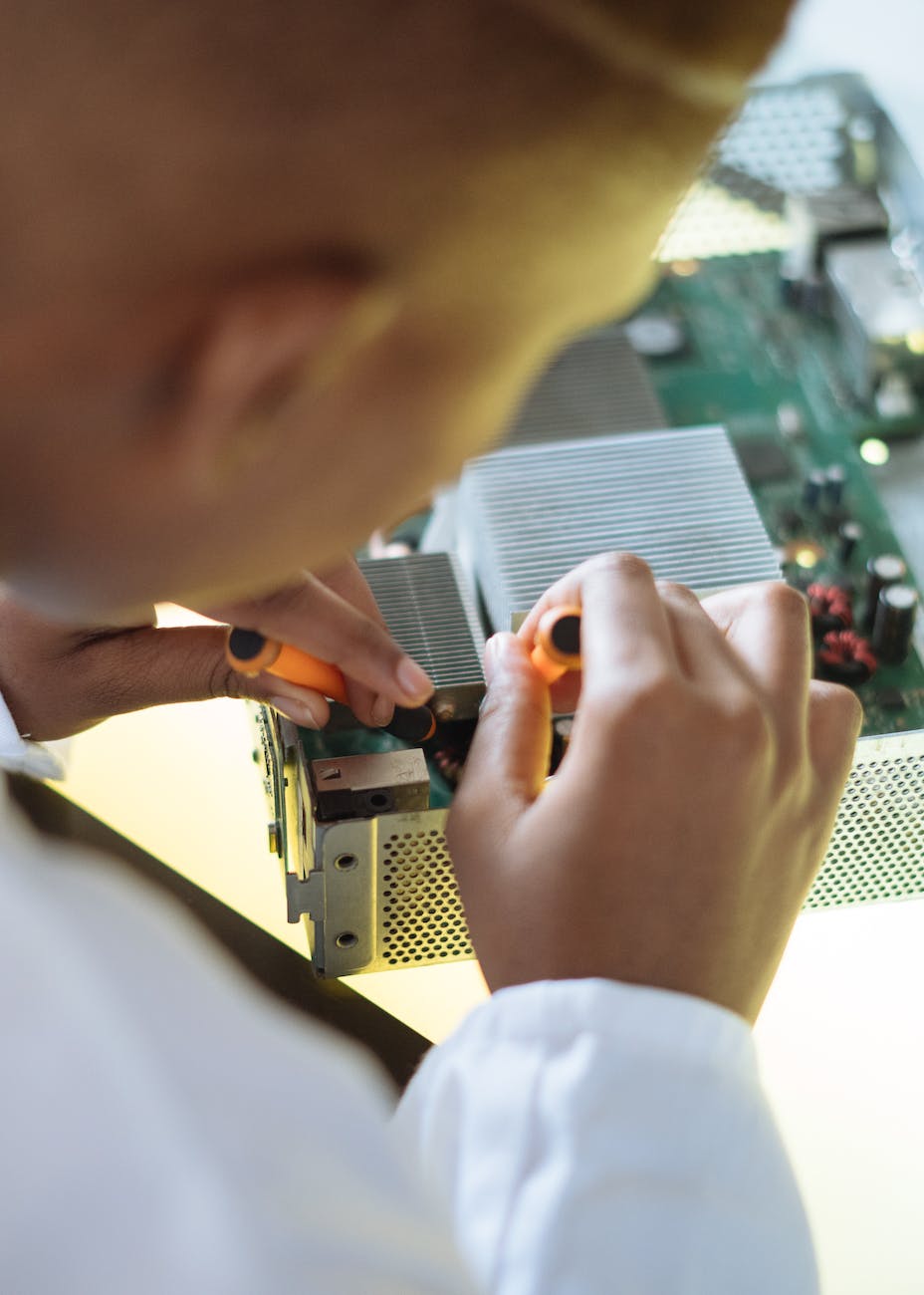

I’m writing this blog in reaction to the news coming from Vertical Aerospace. Their VX4 prototype aircraft was involved in an flight test incident that did a lot of damage[2]. There’s no doubt this incident can provide data to feedback into the design, performance, and safety of future versions of their aircraft[3]. Integrating complex hardware and software is hard but the rewards are great.

“Excellence is never an accident. It is always the result of high intention, sincere effort, and intelligent execution.” – Aristotle

[1] https://youtu.be/Gb_eta4mZkc

[2] https://evtolinsights.com/2023/08/vertical-aerospace-identifies-propeller-as-root-cause-of-august-9-vx4-incident/

[3] https://investor.vertical-aerospace.com/news/news-details/2023/Vertical-Aerospaces-VX4-Programme-Moves-to-the-Next-Phase/default.aspx