Yesterday, I wrote on LH2. The potential fuel for electric aircraft of any size. Yes, I’m not just talking about smaller commuter class transport aircraft.

Let me take some anecdotal evidence from the transition that is going on in road transport. Repairer turns up to fix an electric car that will not start. It’s a simple matter given that the car has been standing unused for a long time. The battery had discharged. A quick charge from another battery pack and all is well. Meantime in conversation it’s clear that the repairer hates working on electric cars. I could say, no surprise, they were trained on combustion engines and have been forced to make a transition in technology.

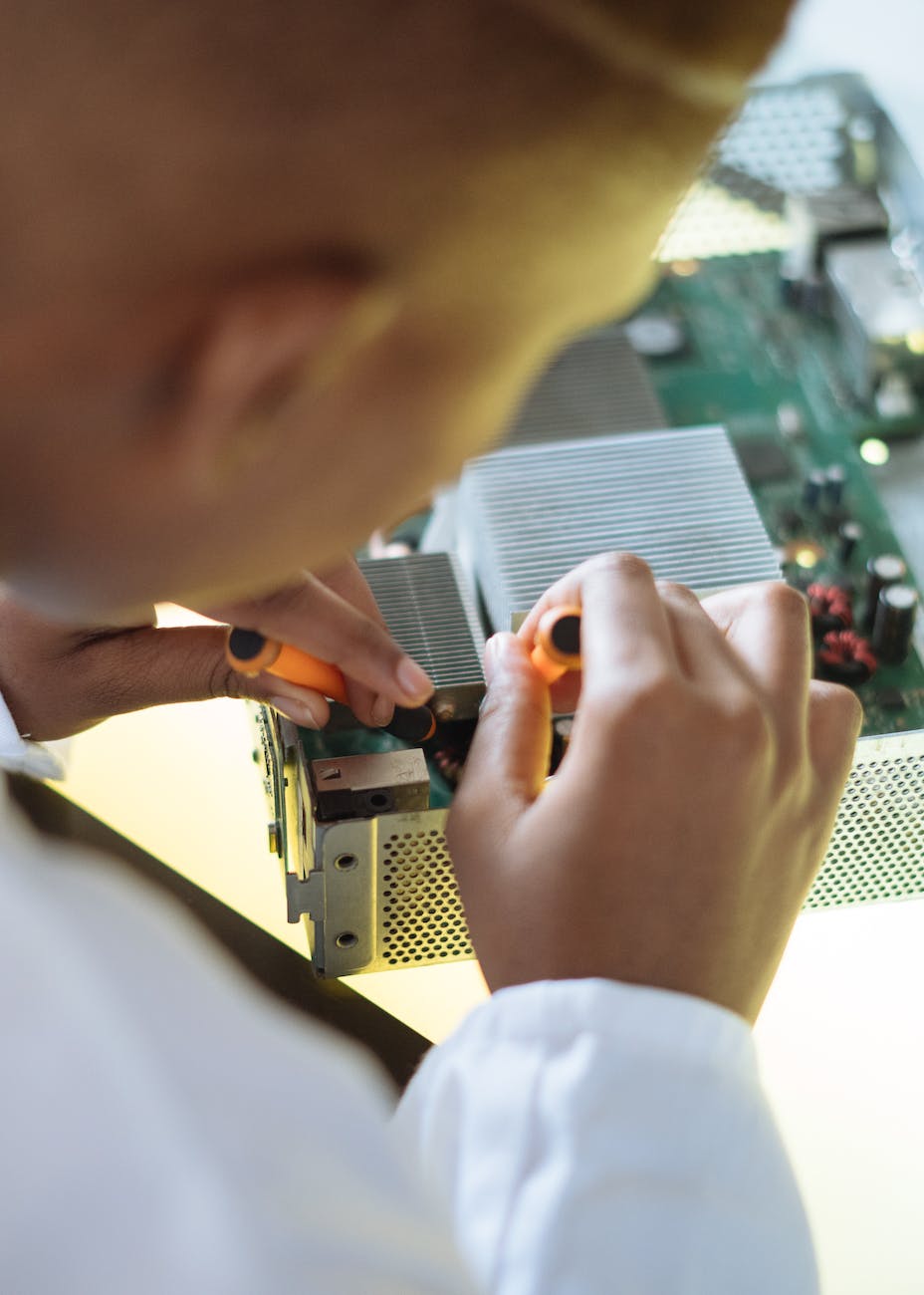

What’s evident here is the apprehension of a person who likely has a mechanical bias towards their work and the necessity to take on fixing powerful electrics. Mechanics, those who love working with moving parts, often have a dislike of electrics and electronics. It’s an engineer’s “feeling” expressed to me casually over the last 40-years.

In fact, it can be the reason that a design or maintenance engineer took the career path that they did. There is a dividing line between mechanical engineers and electrical engineers that is embedded in our institutional, educational, and training systems.

So, there’s two practical human issues to grapple with in a transition:

- Propensity of one branch of technically capable people to find mechanical work less fearsome and more satisfying than electrics or electronics, and

- Streaming that is embedded in our institutional, educational, and training systems. Qualifications and recognition are often not so multi-disciplinary focused.

I’m not for one single moment making a luddite argument that mechanical engineers[1] and electrical engineers[2] are two tribes that must be kept apart. Far from it. What’s more important is to recognise that transitions are hard.

New electric aircraft are going to demand technical people with a multiplicity of both mechanical and electrical knowledge. The way the engineering world has been divided up in the past doesn’t cut it. Some of our most cherished niches will need to be challenged.

Transitions of this nature always take much longer than is originally anticipated. In a way, that should be such a surprise. It’s a generational change for a community that can be conservative with a small “c”.

This is NOT business as usual. For example, handling powerful 1000-volt electric technology is not for everyone. Removing and replacing cryogenic plumbing is, again, not for everyone. The hazards are clear. The skills needed are clear.

Reorienting the aircraft maintenance engineering world is going to need new plans and programmes. Better start by enthusing people about the change rather than just forcing it.